What are the different benefits of using stainless steel fasteners?

stainless steel fasteners

Manufacturers prefer stainless steel the most to make stainless steel fasteners worldwide. Stainless steel has many benefits, making it durable and unique. Although corrosion-resistant steel composites are typically referred to as stainless steel, minute changes in the composite's ingredients could significantly alter the component's mechanical and electrical properties.. The stainless steel composite’s core could be molybdenum, tungsten, copper, nickel, and chromium. This blog discusses the benefits of stainless steel fasteners, which will encourage you to purchase stainless steel fasteners from a wholesale stainless steel fastener supplier. One of those advantages is that stainless steel fasteners that people can easily maintain stainless steel fasteners.

Stainless steel fasteners are corrosion resistant

The main benefit of stainless steel fasteners is that they feature surface protection without additional treatments or surface coatings. This tells us that stainless steel fasteners are incredibly durable and corrosion-resistant. These steel fasteners keep the conventional low composite steel fasteners’ strength and can be utilized wherever conventional steel fasteners are required. Stainless steel fasteners retain good corrosion resistance over their long useful lives and keep shining for a more significant time than a conventional low composite steel fastener. Corrosion resistance is necessary for the functioning of stainless steel fasteners because corrosion will lead to failure in their functioning. The corrosion resistance of stainless steel has made it the most demanded material for producing fasteners.

Stainless steel fasteners can self-repair

The slim chromium oxide film present on the external coating of the stainless steel fastener utilizes oxidation to battle against oxidation. Besides making the fastener corrosion-resistant the oxide coating also lets the fasteners self-repair. If a dent or scrape or any other physical alteration breaks the fastener. On the exposed coating, oxidation results in the formation of another chromium oxide coating, safeguarding it against further corrosion. Here it is necessary to mention that although stainless steel features corrosion resistance it is not corrosion-proof. If people do not install the fastener appropriately, if it has insufficient exposure to oxygen( which averts the formation of chromium oxide layer) or if excessive steel atoms are left on the parts during the production of the fastener. The likelihood of the corrosion of fasteners is significantly higher than in perfectly produced stainless steel fasteners. Thus, people should buy perfectly manufactured stainless steel fasteners and install them properly.

Stainless steel fasteners have a long life

Since stainless steel offers exceptional durability, people can use stainless steel fasteners underwater and expose them to extreme temperatures. No other substance could provide such long-lasting advantages, or at any rate, not until people invest huge amounts of money in it. Whereas the stainless steel fasteners’ original cost could be high, they are cost-efficient in the long run. People would save more time by using stainless steel fasteners, as they need to replace them only once in a few periods.

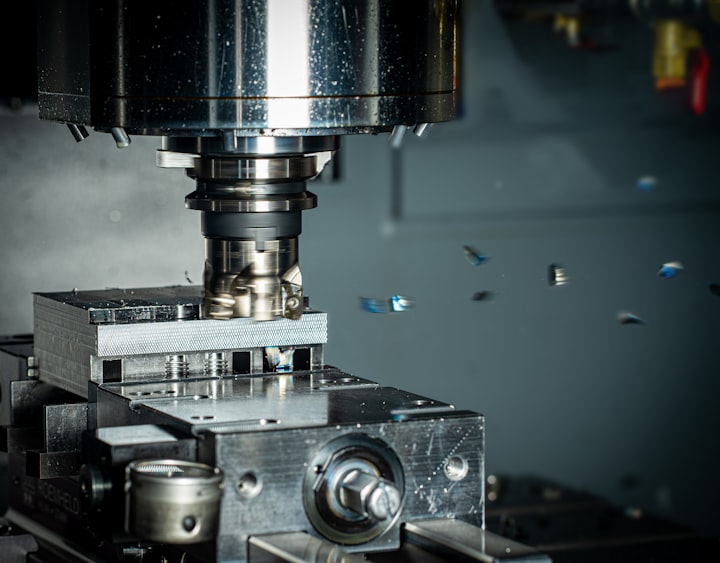

Stainless steel fasteners seem better

People cannot deny the visual appeal brought by stainless steel to every construction. Its sleek yet rugged appearance has even encouraged vehicle makers, manufacturers, and builders to permit the fasteners to show where they are being. Suppose people compare the appearance of the machinery made utilizing stainless steel fasteners with that of the machinery made utilizing fasteners composed of other substances. In that case, they will note that because of its anti-corrosion qualities, the machinery made by using stainless fasteners looks much better. In addition to everything, possibly the stainless steel fasteners’ most tempting benefit is convenience.

Two mos popular stainless steel fastener composites

Generaly speaking, a few different types of stainless steel fasteners are used most frequently to create machines. These two composites, which come in a wide range of specifications and sizes for fasteners, are made of 300° stainless steel. As known by their names, both composites are from the three hundred group of stainless steel, but their mechanical qualities differ due to their chemical composition.

Three hundred and four stainless steel is more commonly utilized than three hundred and sixteen stainless steel. It is composed of Nickel and Chromium. Manufacturers use three hundred and four stainless steel to make automobile parts, pressure vessels, kitchen equipment, and pipelines. However, unlike three hundred and four stainless steel, which is made of nickel and chromium, three hundred and sixteen stainless steel has extra molybdenum that was added particularly to prevent salt corrosion. Due to this, three hundred and sixteen stainless steel will offer higher corrosion resistance in common atmospheres that are more eroding than open-air atmospheres like oceanic applications. To attain this greater degree of performance, the cost of the basic substance is higher whenever compared to three hundred and four stainless steel fasteners. Manufacturers could use three hundred and sixteen stainless steel fasteners to manufacture boats and other machinery designs where fasteners might be exposed to unusually corrosive environments.

Comments

There are no comments for this story

Be the first to respond and start the conversation.